12.29.2010

12.28.2010

Goodbye exposed brick

Hello plywood!

In an effort to improve the R-value (insulation) on our northern wall in the kitchen we decided to wrap the plywood onto the exposed brick wall. We were also vacuuming twice a week because of all the calcium that was flaking off the bricks. Exposed brick sounds cooler than it is!

This project will surely fix both problems while adding even more oak to the kitchen. Trying to make it a 1-day job, and things are looking good!

12.20.2010

devinylizing

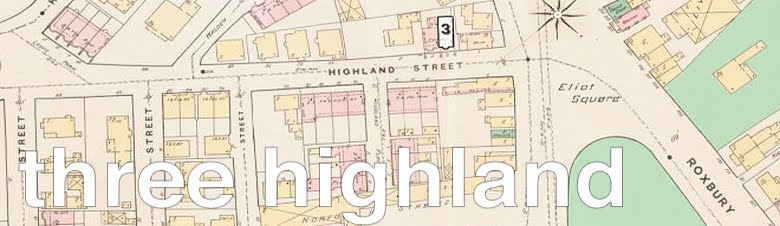

The moment we've all been waiting for with regards to the outside of 3 Highland has arrived. Over the last week, we have removed all of the vinyl on the bay window, and replaced it with mahogany vertical siding.

This wasn't a simple endeavor, as there was quite a bit of rotten plywood beneath the vinyl, which I suppose is why it was vinylized in the first place. A new layer of OSB (oriented strand board...like plywood) went on first to give a solid surface to nail to.

Then went two layers of tar paper, which waterproofs the plywood should any water get behind the mahogany. Next, we taped off all the seams with bituthene membrane. This helps bind the tar paper to the window sills, and has a self-healing layer that prevents nail holes from letting water penetrate towards the house.

The Mahogany was picked up at Building Supply Outlet in Peabody, MA as an overstock item, drastically reducing the price (normally $8/linear foot) to $1/linear foot. This was the same place we found the oak plywood for the kitchens walls and ceiling.

Since the boards had some blonde parts (probably why they weren't considered defective/overstock), we cut the boards in half lengthwise. This allowed us to evenly distribute the blonde boards across the bay window. without large swaths of blonde mahogany.

The snow started falling today and slowed down production, but we will be back at it tomorrow, hopefully finishing the entire project in the morning. Once it's all done, I will show a more official before and after, but here is one for starters.

How will we finish the mahogany? I don't know. I support letting things age naturally, but could also see oiling the boards as a way to preserve their redness. Also want to paint the window frames charcoal grey. Both will be spring time projects.

11.06.2010

Mid construction

Deck takes shape and dries out. We used recycled mahogany from BMRC in Roxbury for the decking and new Pressure Treated 2x8s for the structure.

.

.

Deck replaced

Due to a large amount of water damage, we replaced all the structure and rotted decking for the first floor apartment's deck.

Kathy was in charge of the saws-all, and all fingers are still in tact.

Kathy was in charge of the saws-all, and all fingers are still in tact.

10.15.2010

Subscribe to:

Posts (Atom)